In the annual budget war room, Health, Safety, and Environment (HSE) training is often categorized as a “sunk cost”—a mandatory expense for regulatory compliance that offers no immediate financial return. This is especially true for fire safety, where logistics and material costs often spiral out of control.

However, the narrative is shifting. The adoption of Virtual Reality (VR) in industrial training is no longer a futuristic gimmick; it is an aggressive strategy to slash Operational Expenditure (OPEX).

Why are multinational corporations pivoting to solutions like VGLANT? The answer is simple: Mathematics. Here is a data-driven breakdown of how VR simulation drastically undercuts the cost of conventional fire extinguisher handling methods.

1. Erasing Consumable Costs

Let’s audit the price tag of traditional training. Every time an employee squeezes the lever of a real extinguisher during practice, the company burns cash.

Refill Fees: Discharged canisters must be serviced and refilled. The cost of replacing Dry Chemical Powder (DCP) or CO2 multiplies rapidly across hundreds of employees.

Asset Depletion: Companies often use units nearing their expiration date for training. This is poor asset management; those units should remain active reserves until the very last day of their lifecycle.

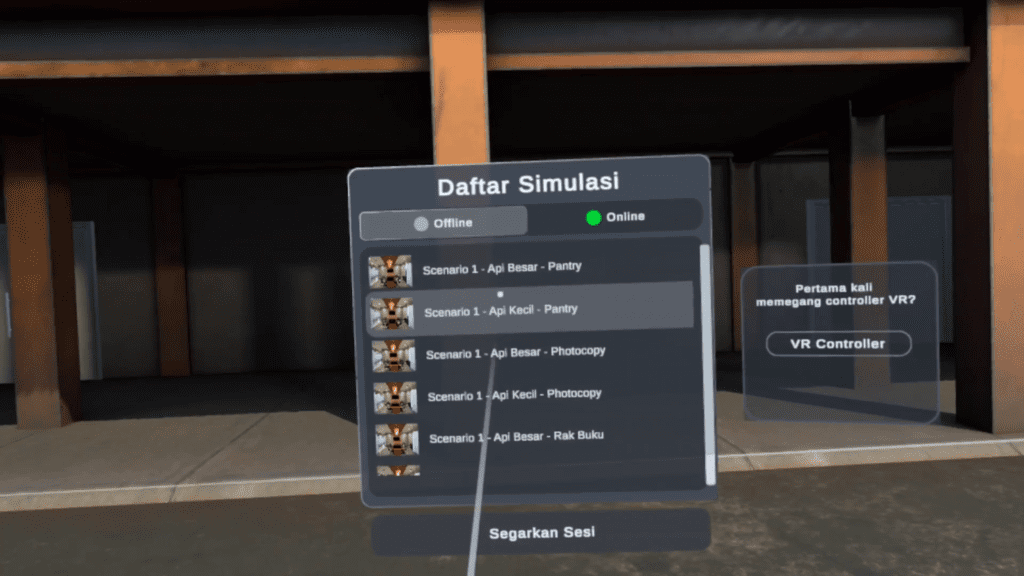

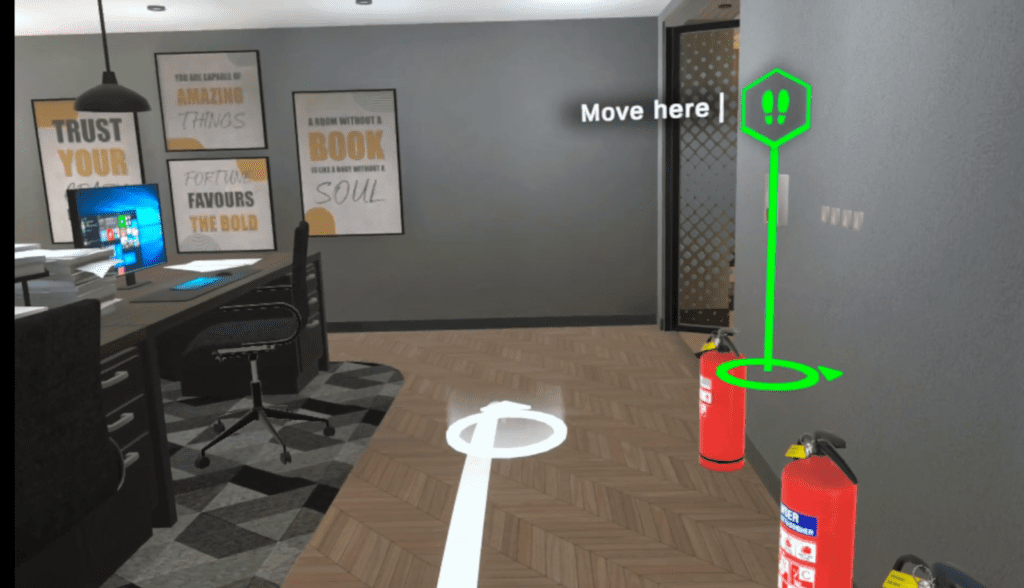

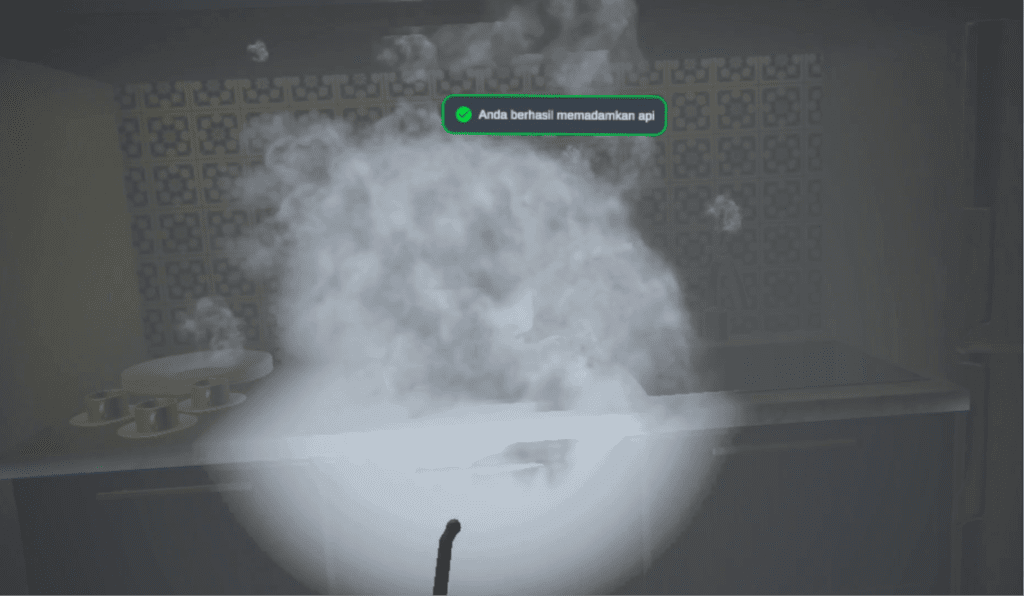

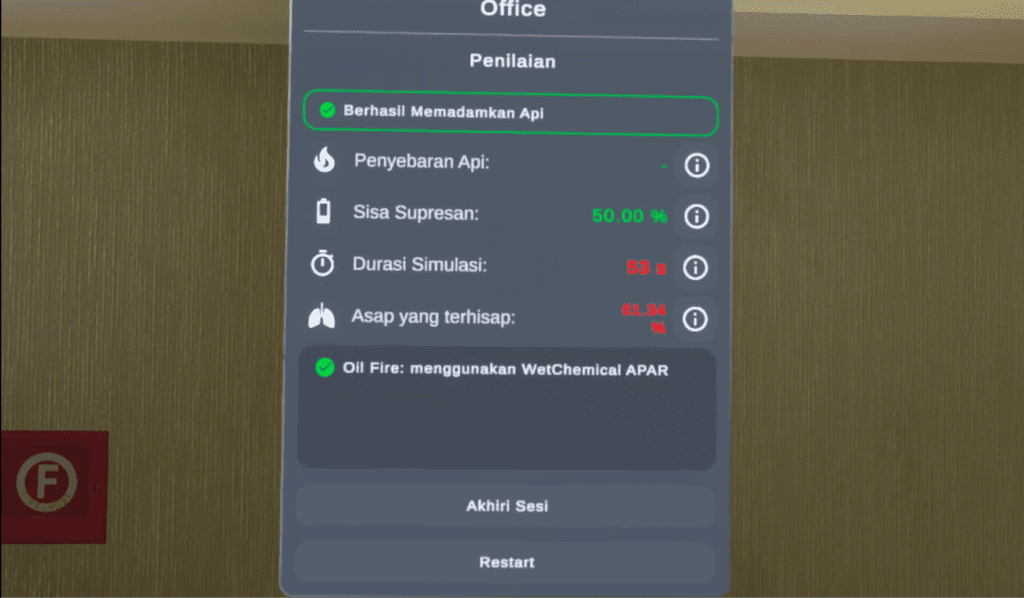

With VGLANT, this variable cost drops to zero. Fire extinguisher handling in VR is entirely digital. An employee can extinguish a virtual fire 50 times in a row without wasting a single gram of chemical agent. The investment is upfront (hardware/software), and the subsequent “cost per use” plummets effectively to zero over time.

2. Stopping the “Downtime Bleed”

The most expensive line item in training isn’t the instructor or the equipment; it is lost productivity. Consider the traditional workflow:

Employees disrupt work to walk to a designated outdoor safety yard.

They wait in long queues for a 10-second turn at the fire pan.

They walk back to their stations.

This process can consume 1 to 2 hours per session. Multiply that by the hourly wage of your workforce, and the financial leakage is staggering.

VR solutions eliminate this logistical nightmare. VGLANT systems are portable and can be deployed instantly in a breakroom or conference hall mere steps from the work floor. Training duration is compressed into high-intensity 15-minute slots per person with zero “wait time.” Productivity remains high, and operational downtime is minimized.

3. Eliminating Environmental & Cleanup Liabilities

In the age of strict ESG (Environmental, Social, and Governance) standards, burning diesel or spraying chemicals into the soil for practice is a liability.

Cleanup Labor: DCP residue is corrosive, messy, and hazardous to inhale. Post-training cleanup requires additional labor hours and specialized disposal.

Regulatory Fines: Open burning permits are becoming harder to secure, and violations carry heavy fines.

Transitioning to VR-based fire extinguisher handling is an instant “green” win. There is no real fire, no smoke, and no chemical waste. The company avoids soil contamination risks and the associated remediation costs entirely.

4. Infinite Scalability, Zero Travel Costs

What is the cost of flying a certified master trainer to a remote mining site or an offshore rig? Between flights, accommodation, and visa processing, the logistics often cost more than the training itself.

VGLANT technology democratizes training quality. The exact same high-standard module used at Headquarters in Jakarta can be deployed at a remote site in Kalimantan without ever putting a trainer on a plane. The quality of instruction is consistent, standardized, and immune to human fatigue. This is logistics efficiency at its peak.

Conclusion: A Real ROI

Switching to VR isn’t about chasing a tech trend. It is a calculated business decision. By eliminating material waste, slashing non-productive hours, and removing environmental risks, VGLANT offers a Return on Investment (ROI) that pays for itself in record time.

The question is no longer “Is VR too expensive?” The real question is, “How much money are we burning every year by sticking to the old methods?”

Contact Us

Ready to audit your training efficiency?

Contact us to discuss how VGLANT can significantly reduce your corporate safety budget while improving readiness.

Call / WhatsApp: +62 812 9696 7887

Email: inquiry@vglant.com

Website: www.vglant.com